Custom Moulding

-

Estimated delivery: -

-

Tracked delivery through DX Courier’s Large & Bulky Service. You’ll receive a text with your delivery slot prior to the scheduled day.

Safe and secure checkout guaranteed, with all major payment methods supported: Visa, MasterCard, PayPal, Apple Pay, Google Pay, and more.

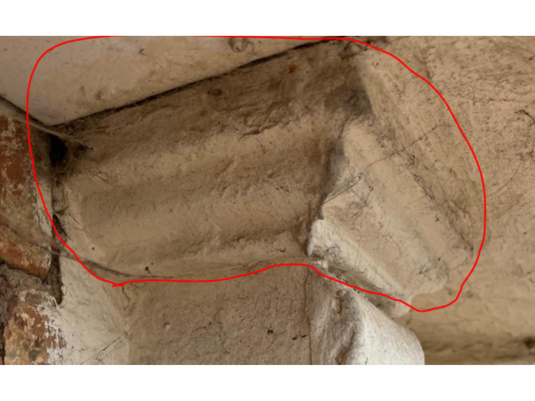

Custom Mouldings – Made to Order, Just for You

Tailored Designs to Meet Your Exact Specifications

At UKCoving, we specialise in creating bespoke mouldings that align perfectly with your design vision. Whether you're looking for something unique or need a slight variation of an existing model, our custom moulding service is here to turn your ideas into reality. Simply let us know your requirements, and we’ll assist you every step of the way.

How It Works

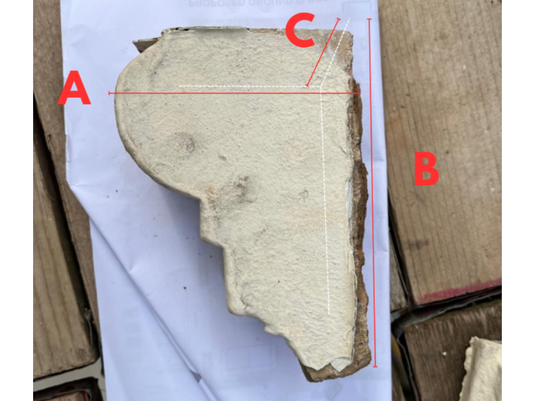

Provide a Drawing for Precision

For the most accurate result, we recommend submitting a drawing of your desired shape and dimensions. This ensures that the final product meets your exact specifications. Don’t forget to include how many metres you need, as our production lines are optimised to produce mouldings in 2-metre lengths, with a minimum order of 2 metres.

No Drawing? No Problem

If you’re only looking for minor adjustments to our standard mouldings, a detailed drawing may not be necessary. We’ll work closely with you to understand your needs and create the perfect solution.

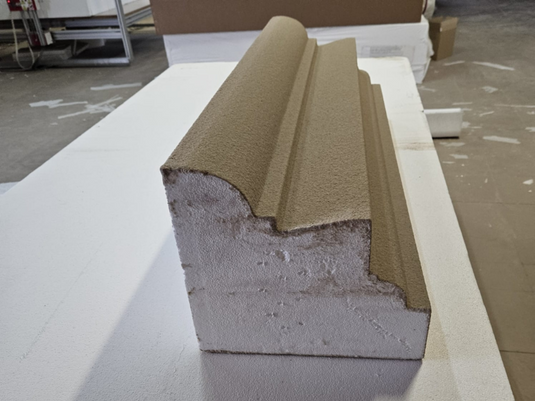

Material Options

Our custom mouldings can be produced from either XPS or EPS plaster-coated materials. We recommend EPS for a premium, durable finish that’s water-resistant and fire-retardant. We'll advise you on the best material based on your specific project requirements.

The Importance of Details

The more information you provide, the easier it is for us to craft the exact moulding you need. From dimensions and design intricacies to materials and quantities, every detail helps us ensure precision.

Shipping and Pricing Considerations

Please include your shipping address when placing your order, as this may affect the overall cost. We’ll provide a comprehensive quote that covers both production and delivery.

Ready to create your custom moulding? Contact us today, and we’ll guide you through the process to bring your design to life!

When you place an order with us, it goes straight into our production queue. For XPS covings without plaster coating, the lead time is typically 3-6 working days. However, for plaster-coated mouldings, which require proper drying time, the lead time extends to 8-12 working days. We never rush production as we are committed to delivering the highest quality product, ensuring your complete satisfaction.

Returns or exchanges must be reported within 14 days of delivery. If not reported in advance, we may decline the return. To qualify for a full refund, goods should be returned within 30 days of receipt, unused and undamaged. Please note, we reserve the right to refuse returns after this period.