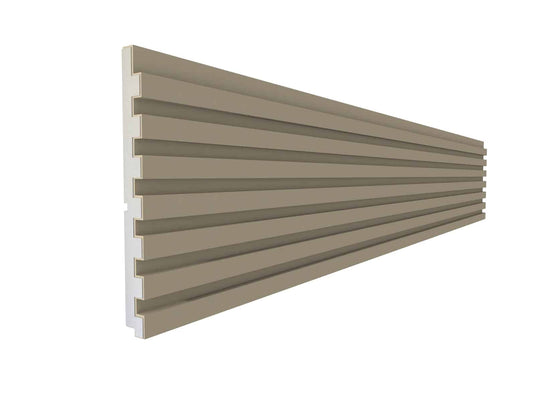

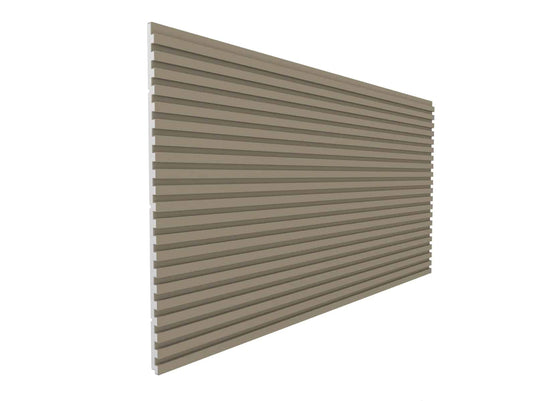

Slatted 3D Wall Panel Plaster Coated PN-14 360mm x 32,5mm x 2000mm

-

Estimated delivery: -

-

Tracked delivery through DX Courier’s Large & Bulky Service. You’ll receive a text with your delivery slot prior to the scheduled day.

Safe and secure checkout guaranteed, with all major payment methods supported: Visa, MasterCard, PayPal, Apple Pay, Google Pay, and more.

Transform Your Exterior with Our 3D Decorative Wall Panels

Enhance your building’s exterior with our premium 3D Decorative Wall Panels, crafted from durable polystyrene and coated with a tough acrylic finish. Designed to combine visual appeal with outstanding durability, these panels offer long-lasting protection and style.

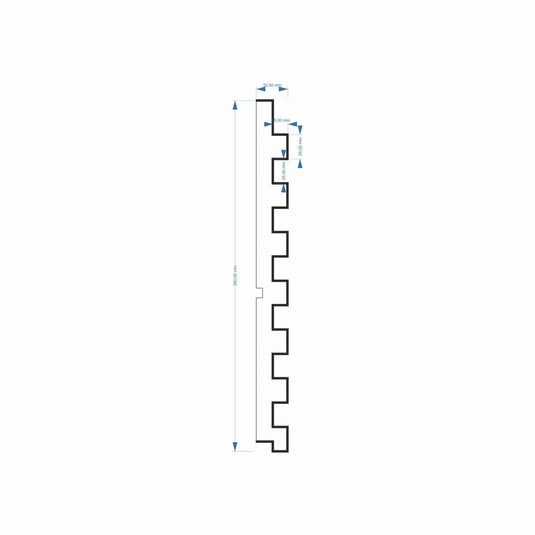

Dimensions and Weight:

-

Dimensions: 360mm (width) x 32.5mm (depth) x 2000mm (length)

Each panel is designed for exterior use, covering large areas with ease.

Superior Quality and Longevity

The material composition ensures that our mouldings do not warp, crack, or fade over time, maintaining their pristine appearance for years. Whether you require exterior wall mouldings or cornice mouldings, our products are designed to meet the highest standards of quality and performance.

Key Features:

-

Effortless Installation: Lightweight and easy to install either horizontally or vertically, using exterior solvent-free adhesives. Panels are flexible, making them easy to fit on various surfaces. In addition to all that, the panels are perfectly interlocking guaranteeing seamless joints!

- Weatherproof & Durable: Coated with a machine-applied, strong acrylic layer, these panels resist weather, impacts, and pressure. They are also prepped for painting with silicone-based paints.

- Resilient and Long-Lasting: Built to handle extreme weather conditions, offering excellent protection against environmental factors like rain, temperature fluctuations, and UV exposure.

Why Choose Us?

-

Unique Manufacturing: Produced using state-of-the-art machine-coating technology, ensuring a smooth, durable surface that withstands daily wear and tear.

-

Long-Lasting Quality: Shock-resistant and 90% lighter than traditional concrete, making it easier to handle without sacrificing durability.

-

Customisable Options: Supplied in 2-metre lengths (+-0.5%) with optional end-caps available for a tailored finish.

Whether you’re renovating a heritage property or adding a decorative touch to a new build, our Plaster-Coated Window Frame Cornice is the perfect choice for homeowners and developers alike.

Combine elegance with performance and protect your exterior with a solution that lasts for years.

Easy Installation and Maintenance

The coving can be customised to fit your specific dimensions, ensuring a perfect fit for any space.

When you place an order with us, it goes straight into our production queue. For XPS covings without plaster coating, the lead time is typically 3-6 working days. However, for plaster-coated mouldings, which require proper drying time, the lead time extends to 8-12 working days. We never rush production as we are committed to delivering the highest quality product, ensuring your complete satisfaction.

Returns or exchanges must be reported within 14 days of delivery. If not reported in advance, we may decline the return. To qualify for a full refund, goods should be returned within 30 days of receipt, unused and undamaged. Please note, we reserve the right to refuse returns after this period.